Blog

EVLO’s Test Line Facility is Setting a New Standard for BESS Safety and Performance

November 14, 2024

In today’s rapidly evolving energy landscape, utilities and independent power producers (IPPs) face increasing pressure to meet global net-zero targets while ensuring grid reliability. As the demand for clean energy skyrockets, relying on a safe and efficient energy storage solution has never been more critical, to make the most out of renewable energy.

Reliability of energy storage solutions isn’t just theoretical—it’s operational reality.

At EVLO, we go beyond industry standards to test our BESS under the most extreme scenarios, under live grid conditions, and ensure that they can withstand harsh conditions while maintaining optimal performance. We commit to delivering systems that are ready for anything the grid demands, so that utilities and IPPs can focus on delivering stable, affordable power to their customers.

Real-World Testing for Real-World Performance

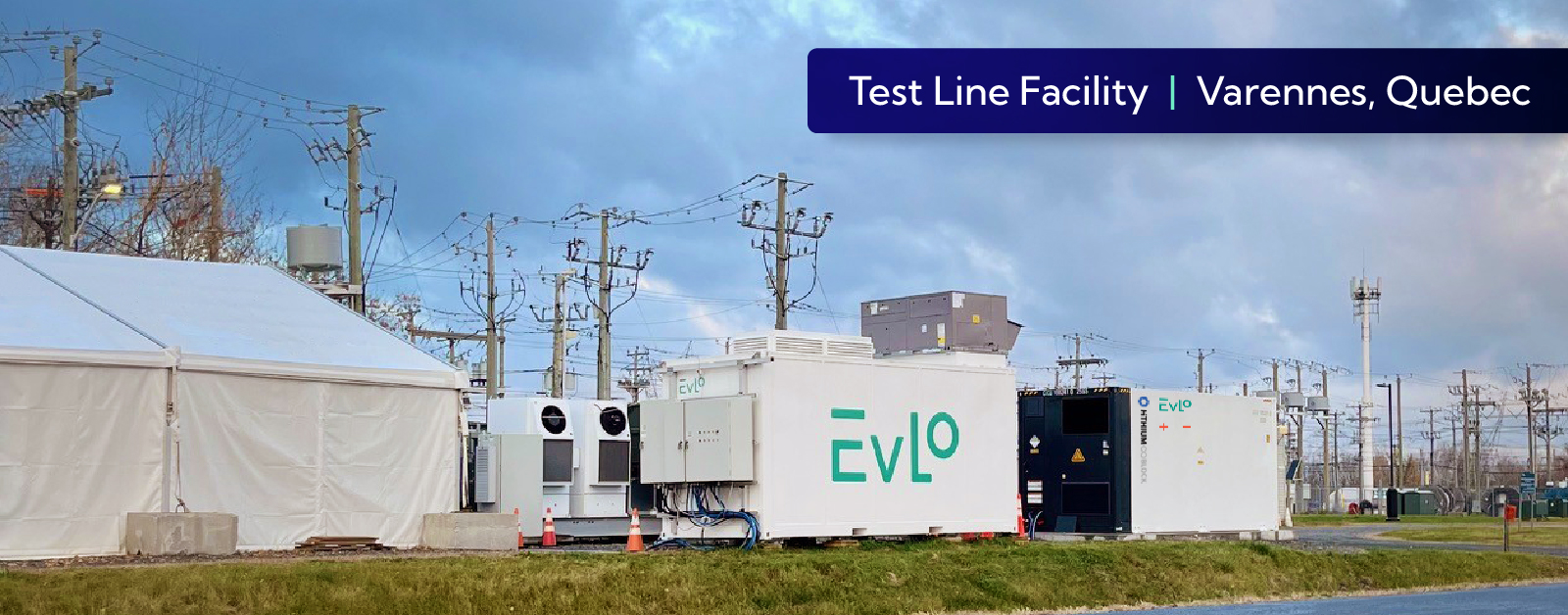

While Functional Integration Testing (FIT) in indoor laboratories is a common approach to BESS validation, a system’s performance is most accurately assessed by observing how it operates in actual live grid conditions. This is why, very early on, EVLO developed an advanced test line at IREQ (Institut de recherche d’Hydro-Québec), a world-renowned electricity research center, which serves as a critical innovation hub for both Hydro-Québec and EVLO, allowing for joint R&D in cutting-edge technologies and testing methodologies.

The state-of-the-art test line facility, neighboring our headquarters in Varennes (Québec), enables the connection of our BESS to a 25-kilovolt (kV) distribution grid and the validation of their performance before installation, commissioning, and operation.

By conducting FIT on a utility-grade test line connected to a live distribution network, we’re able to push our systems to their limits and beyond, identifying potential issues that may only surface during commercial operation and ensuring that the technologies can operate safely and effectively. Our systems being exposed to actual operational conditions, we can better identify edge cases and improve product safety and performance while delivering on our commitment to meeting stringent safety and performance standards and minimizing risks for end users.

Comprehensive Testing for Uncompromising Quality

What exactly happens in our cutting-edge labs? EVLO’s FIT process, meticulously designed to ensure comprehensive system operational readiness, encompasses four primary stages:

1. Performance and Stress Testing:

Our systems are subjected to repeated cycles of charging and discharging to simulate years of use in just a short time to show our clients how the batteries perform over time and under various operational stresses.

2. Thermal Runaway and Fire Safety Testing:

Our systems are tested to validate the responsiveness of alarms and fire prevention measures in the event of thermal runaway.

3. Environmental Testing for Resilience:

BESS must be reliable regardless of the climate and environments they are deployed in. By thoroughly testing our systems, we ensure their consistent performance even in the most challenging environments.

4. Firmware Updates and Real Time Testing:

As technology evolves, keeping BESS systems up to date is crucial for efficiency and reliability. By testing firmware updates in real-time conditions, we ensure that our systems run with the latest optimizations and features.

De-Risking Projects, Maximizing Performance

The energy storage landscape presents numerous challenges, from ensuring robust cybersecurity to seamlessly integrating with complex grid systems. EVLO’s thorough and rigorous testing process contributes to the success of your project in many ways:

1. Enhanced Safety and Risk Mitigation:

By subjecting our systems to voltage testing up to 25 kV, we ensure they meet and exceed rigorous safety standards.

2. Reliability in the Field:

By testing load-balancing capabilities and system response during peak energy demand or grid instability, we fine-tune our systems’ performance for optimal efficiency before commissioning.

3. Cybersecurity Assurance:

While battery cells themselves don’t pose cybersecurity risks, we rigorously test the security of BESS’ electronic components—from the Battery Management System (BMS) to the Power Conversion System (PCS) and Energy Management System (EMS).

4. Continuous Optimization and Updates:

We test the compatibility of our systems with grid protocols to ensure they maintain optimal performance over time and prevent any surprise post-installation.

5. Long-Term Cost Efficiency:

Before deployment, we can adapt energy storage systems to meet the unique requirements of each project or client. By fine-tuning the system, we ensure flawless integration with a utility’s existing infrastructure. This flexibility is critical to reduce the risk of compatibility issues or costly adjustments after installation.

6. Hands-On Training and Maintenance Readiness:

At EVLO’s testing facility, we welcome operators and maintenance teams for real-world scenarios before installation. Well-prepared operational teams will be better able to handle the system’s complexities, reducing the learning curve and helping utilities and IPPs avoid costly errors. Our test line also provides the opportunity to anticipate concerns from Authorities Having Jurisdiction on how to best integrate BESS into their communities.

The EVLO Advantage

Why do we do all that? By demonstrating the real-world operational readiness of our BESS, we ensure seamless grid integration to your projects—and you receive a solution that works as promised, from day one.

As the acceleration of the energy transition boosts the demand for clean energy, the need for safe, efficient and rigorously tested storage solutions is pivotal. Our advanced testing process in a true-life environment streamlines project development, accelerates project approval while enhancing system reliability to de-risk the commissioning and operations of energy storage projects for utilities and IPPs.

Partnering with EVLO implies more than just meeting today’s demands—it’s about preparing for the challenges of tomorrow with systems that are tested, trusted, and ready to deploy.

Together, let’s power the future—safely, efficiently, and sustainably.